Equip laser systems with Lasermet’s LS-30 and LS-300 Series of Beam Shutters

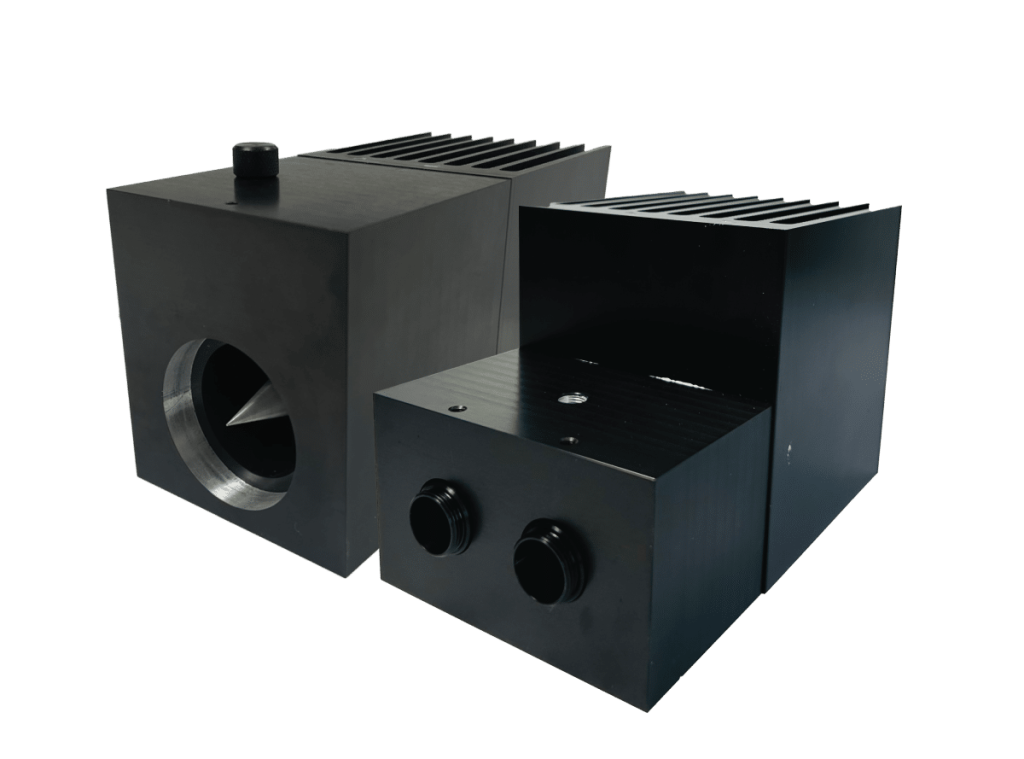

Lasermet launches the LS-30 and LS-300 Series of beam shutters, with its new look and upgraded features.

The LS-30 laser shutters’ standard model and Original Equipment Manufacturer (OEM) model has a spring-loaded shutter blade that enables it to be installed in different orientations and allows the customer to choose the best mounting orientation for any environment. It can be installed in horizontal, vertical and upside-down orientations.

The LS-300 Series of laser shutters handles considerably higher laser power than its predecessor laser shutters. It has three models available having different size beam apertures – 50mm, 75mm and 100mm. The laser shutters larger proportions allows faster dissipation of laser energy using its internal beam dump.

SIL Rated and OEM Model

When correctly wired to Lasermet’s Interlock Control System (ICS) can provide a safety interlock which meets SIL-3 and EN13849-1 up to performance level ‘e’. Incorporate the laser shutter as a built-in safety for laser operating systems using the OEM model. Create a custom laser product when the OEM model is integrated into user equipment.

Laser Shutter to Beam Dump

A laser shutter can handle a considerably high powered laser but it can be attached with a beam dump and increase efficiency of laser energy dissipation and the shutter lifespan.

The LS-30 Series can be used with Lasermet’s BD-20-AC, BD-20-AC-DC and BD-AC-16.

The LS-300-50 can be used with Lasermet’s LS-200-BD-HP and BD-HCX-45.

Shutter Blade Options

The laser shutter blade is an important factor that increases laser shutters efficiency and lifespan. Selecting the proper material depends on the kinds of lasers that will be used during operation. In choosing an optical material for your laser shutter consider these following factors:

- Range of wavelengths

- Maximum Power

- Type of laser

Lasermet offers different shutter blade options for all kinds of lasers. The laser shutters has a standard angled bare stainless steel blade. A ceramic blade option is recommended for Q-switched lasers where the standard stainless steel blade may erode. There are a number of mirror blade options, featuring a front silvered or di-electric mirror depending on the laser operation. These options can be factory fitted to the standard stainless steel blade.

Importance of Laser Shutters

A laser shutter is vital for maintaining safety, ensuring precise control of laser outputs, protecting equipment, and increasing the efficiency of laser-based operations. It helps to ensure that laser systems operate in a controlled and secure manner, which is especially important in high-powered or high-precision applications. The utmost attention is put into implementing proper safeguards for laser operating systems. Lasermet’s shutters are created from high quality materials ensuring its longevity and capabilities under operation. The shutters have been tested and underwent through trial and error to achieve a high level of performance.