LS-10 Series Laser Shutters

Laser Safety Beam Shutters & Beam Dumps

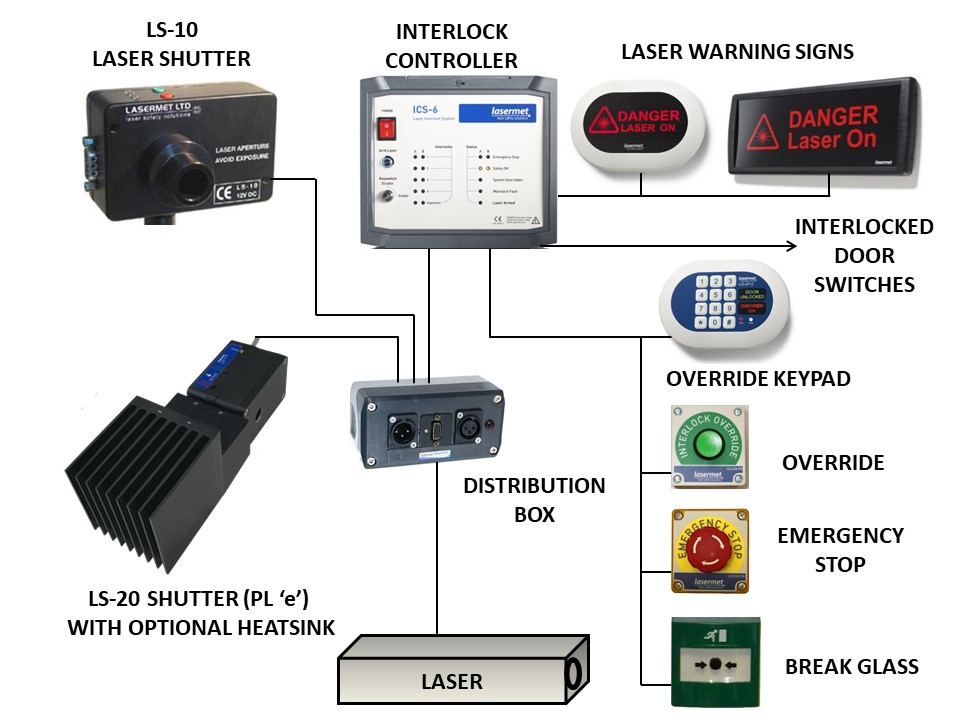

The LS- range of laser beam shutters are combined shutters and beam dumps designed to be driven by a safety control system such as the Lasermet’s Interlock® controller for use as a means of shutting down the laser beam automatically during unauthorised access, or manually when the beam is not required.

They can also be used as stand-alone laser shutters for manual or remote switching of the laser beam.

- Gravity-operated for fail safe control

- Combined shutter and laser beam dump for added safety

- Compatible with interlocked safety control systems

- Safety latch prevents accidental laser beam switch on

- Remote switching option

- Available as OEM product

Description

LS-10 Beam Shutters & Beam Dumps

The LS-10-12 shutters are designed to absorb all the laser beam power thus eliminating the need for an additional beam dump and avoiding hazardous reflections. The laser beam is converted to heat and radiated from the shutter case.

These shutters can be used with lasers up to the maximum average power specified as follows.

- The LS-10-12 is suitable for up to 20W average power.

- The LS-100-12 is air-cooled by a fan and suitable for up to 200W average power.

The LS-100-12 has been discontinued. This page only remains for reference.

OPERATING LOGIC

The shutters will not open unless power is supplied. When power is supplied a yellow LED lights to indicate that power is present. A green LED will also light indicating that the shutter is fully closed. To open the shutter the green button must be pressed. The green LED will go out and an orange LED will light indicating that the shutter is fully open. The shutter can be closed by pressing the red button or by cutting the power.

Opening of any laboratory door without use of the override will result in the shutter closing, thus preventing unprotected persons from exposure to the laser radiation. The shutter is fail-safe and gravity operated so any loss of power will cause the shutter to close without reliance on springs or any other device.

LOW CURRENT REQUIREMENT

Intelligent design results in low current consumption. This increases the number of shutters which can be run from the same power supply and keeps the shutter cool enough for use as a beam dump when closed.

| PART NUMBER | MAX LASER POWER (W) | APERTURE SIZE (MM) | DRIVE VOLTAGE (V DC) | CURRENT CONSUMPTION (MA) | SIZE (MM) |

| LS-10-12 | 20 | 15 | 11 – 14 | 150 | 98 x 63.5 x 36* |

| LS-100-12 | 200 | 50 | 11 – 14 | 150 | 130 x 150 x 140* |

* 100mm including tube

** 175mm including tube

The LS-10-12 and the LS-100-12 shutters work on 12 VDC. However, if your supply is 18-24 VDC or similar, Lasermet provide the LS voltage converter (Part no. LS-VC-24.12) which enables operation from 15 – 35 VDC.

REMOTE SWITCHING STATION

For applications where the LS-10-12 and LS-100-12 laser shutters are used in an enclosure and the buttons cannot be accessed, or for other remote switching requirements, the Remote Switching Station (Part No. LS-RS) can be used to open and close the shutter remotely.

Alternatively, the LS-10-12 and LS-100-12 laser shutters can be put into ‘switch bypass mode’ by changing some internal links on the PCB inside the shutter. In this mode the shutter will open immediately when the power is applied and close when the power is turned off.

REMOTE INTERLOCK® BOARD

An optional Interlock® board (part no: LS-10-IB) can be fitted, providing two volt free contacts, one normally open and one normally closed, which can be used to Interlock® another device to the shutter status. These contacts are rated at 2A and 30 VDC.

FIXINGS

The LS-10-12 has a single M6 thread in the base and can be mounted to a breadboard by use of an optical pin.

The LS-100-12 has four M6 mounting threads in the base. It can be mounted on a breadboard at any angle, by use of the mounting plate pack LS-100-MP and metric (LS-100-MAS) or imperial (LS-100-IAS) mounting screws.